Adil Writer & His Mad Ceramic Wall Hangings. Mandala Pottery, Auroville.

Whilst visiting the Dana Community, I saw Adil Writer and Anamika making pieces for the wall. I had been thinking about this possibility, as it seems that people are more willing to buy art that hangs on the wall rather than sits on a shelf (or at least they're willing to pay more for it).

Until I saw the finished result I was dubious as to whether these pieces would work. It seemed like Adil and Anamika were just throwing old bits of dry clay on thick square slabs. Adil told me he never recycles clay to be thrown with again, instead letting it dry out and then using it for pieces like this. As the layers built up, forms took shape. The work was very fast and spontaneous, no time for thinking or conceptualizing.

I thought this was the end of them. Ready for firing. So went around and saw what everyone else was up to, taking some pics and videos of the other potters at work. After some time (in India people always tell you things will happen in "some time"), someone came to tell me Adil wanted to show me something.

When I got back he was already in full flow, slapping the square slabs on the concrete floor. Not once or twice but many times; he didn't even stop when the slabs ripped and tore in pieces. I thought this was utter madness, but he seemed to have done it before.

After this I was led to another workspace where larger squares of clay had been laid out, all cross-hashed and slipped, ready to accept a shaggy crust.

The solid backing gives the torn surface pieces support and allows them to be hung safely. During the firing the top layer curls up like a lily pad. Here is a finished one:

After the performance Adil invited me upstairs to the studio where a lot of his finished works were hanging around, waiting to be shipped off for exhibitions.

Hands littered the floor.

Before I left I popped my head in another little space and found a selection of large platters.

And some finished ones:

So that's a taster or the ceramics being made at Mandala Pottery. Next post will be about the pottery where most of the potters in the Dana Community trained: Golden Bridge Pottery in Pondicherry.

Until I saw the finished result I was dubious as to whether these pieces would work. It seemed like Adil and Anamika were just throwing old bits of dry clay on thick square slabs. Adil told me he never recycles clay to be thrown with again, instead letting it dry out and then using it for pieces like this. As the layers built up, forms took shape. The work was very fast and spontaneous, no time for thinking or conceptualizing.

|

| Each slab got numerous different clays on it. |

|

| Crumbly surface. |

|

| The final splosh on each was red iron oxide, liberally applied. |

|

| Bloody corner. |

I thought this was the end of them. Ready for firing. So went around and saw what everyone else was up to, taking some pics and videos of the other potters at work. After some time (in India people always tell you things will happen in "some time"), someone came to tell me Adil wanted to show me something.

When I got back he was already in full flow, slapping the square slabs on the concrete floor. Not once or twice but many times; he didn't even stop when the slabs ripped and tore in pieces. I thought this was utter madness, but he seemed to have done it before.

|

| There it goes. |

|

| And again. |

|

| Never mind those tears. |

After this I was led to another workspace where larger squares of clay had been laid out, all cross-hashed and slipped, ready to accept a shaggy crust.

|

| The surface of the clay slapped n the floor was stretched and cracked-a nice effect even unfired. |

|

| Anamika and Adil played with the 3D possibilities of the technique, too. |

|

| Mini mountain range. |

|

| Up close. |

The solid backing gives the torn surface pieces support and allows them to be hung safely. During the firing the top layer curls up like a lily pad. Here is a finished one:

|

| Ready for the wall. |

Hands littered the floor.

|

| Spooky. |

|

| How did it get so late so soon? |

Before I left I popped my head in another little space and found a selection of large platters.

|

| Sturdy feet. |

|

| Ready for glazing. |

|

| Textured surface. |

And some finished ones:

|

| You can see the same idea of playing with texture in the platters as the wall hangings. |

|

| Nice swish. |

|

| I love the mad crackle glaze mixed with the blue. |

So that's a taster or the ceramics being made at Mandala Pottery. Next post will be about the pottery where most of the potters in the Dana Community trained: Golden Bridge Pottery in Pondicherry.

The Dana Pottery Community, Auroville, Part 3 (Oil Burners)

The instant I saw this potter making oil burners, I was interested. Unusually so, because of a terrible mistake I'd made earlier in our trip around India. It began in Mysore, at a lovely indoor market where two brothers beckoned us into their shop...

We didn't really want to go in but they insisted, giving us a demonstration on how to make incense sticks. Reasonably interesting stuff. "Chai?" they asked. "Sure," we said. The shop was founded by the brothers' grandfather (greasy pictures on the wall attested this) and it specialises in oils of all sorts. They let us smell the selection: jasmine, lotus, lemongrass, rose, sandalwood... you name the flower and he had the oil. Decanters lined the walls. You can easily make your own perfume by adding five or so drops to 100ml of high % alcohol. This idea intrigued me, and I thought about the possibility of doing this in the future, and blowing some more perfume bottles to put them in. (I have blown a few and it's great fun). They told us you can post the oils home, no problem. We were charmed good and proper, and left with eight little glass bottles bearing 40ml of fine-smelling oil. They were wrapped up decently with string, and came with a free wad of incense.

I kept them in the middle of my roll of clothes and carried my back pack tentatively all the way to Kochi. In Kochi we try to post them home with a whole load of spices, knives and other things we'd picked up. "No oils," the postmaster said. Oh dear. So I've been carrying this fragile package around for the last two months, trying not to damage it. My backpack now smells like the inside of Chanel's bathroom, and I'm pretty sure one or more of the bottles has exploded. I put them in a cardboard box inside a plastic bag and by now the cardboard is soaked and disintegrating, the bag all sloppy inside.

But I still have hope some of the glass vials are intact. The way that most people use these oils in India is by putting a drop or two in the top of a burner, with a candle underneath, so the smell slowly fills the house. If I have any bottles intact by the time I get home, I want to make a few of these and try it out.

So. When I arrived, the potter was throwing the tops of the burners, the bottoms already completed. He was throwing them off the hump at great speed, putting in the final swish with a practiced hand.

Le video:

Next up, trimming:

And then joining. Here are the bodies ready for their tops:

A joined one, up close:

Gorgeous workshop. The afternoon light was spectacular through these windows. The little holes cut into the sides of these oil burners will create a similar effect when a candle is lit inside.

Post-handling:

Here they are lined up to dry, ready for firing.

In the kiln they go.

We didn't really want to go in but they insisted, giving us a demonstration on how to make incense sticks. Reasonably interesting stuff. "Chai?" they asked. "Sure," we said. The shop was founded by the brothers' grandfather (greasy pictures on the wall attested this) and it specialises in oils of all sorts. They let us smell the selection: jasmine, lotus, lemongrass, rose, sandalwood... you name the flower and he had the oil. Decanters lined the walls. You can easily make your own perfume by adding five or so drops to 100ml of high % alcohol. This idea intrigued me, and I thought about the possibility of doing this in the future, and blowing some more perfume bottles to put them in. (I have blown a few and it's great fun). They told us you can post the oils home, no problem. We were charmed good and proper, and left with eight little glass bottles bearing 40ml of fine-smelling oil. They were wrapped up decently with string, and came with a free wad of incense.

I kept them in the middle of my roll of clothes and carried my back pack tentatively all the way to Kochi. In Kochi we try to post them home with a whole load of spices, knives and other things we'd picked up. "No oils," the postmaster said. Oh dear. So I've been carrying this fragile package around for the last two months, trying not to damage it. My backpack now smells like the inside of Chanel's bathroom, and I'm pretty sure one or more of the bottles has exploded. I put them in a cardboard box inside a plastic bag and by now the cardboard is soaked and disintegrating, the bag all sloppy inside.

But I still have hope some of the glass vials are intact. The way that most people use these oils in India is by putting a drop or two in the top of a burner, with a candle underneath, so the smell slowly fills the house. If I have any bottles intact by the time I get home, I want to make a few of these and try it out.

So. When I arrived, the potter was throwing the tops of the burners, the bottoms already completed. He was throwing them off the hump at great speed, putting in the final swish with a practiced hand.

| |||

| Oil burner tops. |

|

| Le hump |

Next up, trimming:

And then joining. Here are the bodies ready for their tops:

A joined one, up close:

Gorgeous workshop. The afternoon light was spectacular through these windows. The little holes cut into the sides of these oil burners will create a similar effect when a candle is lit inside.

Post-handling:

Here they are lined up to dry, ready for firing.

In the kiln they go.

The Dana Pottery Community, Auroville, Part 2 (Candle Holders)

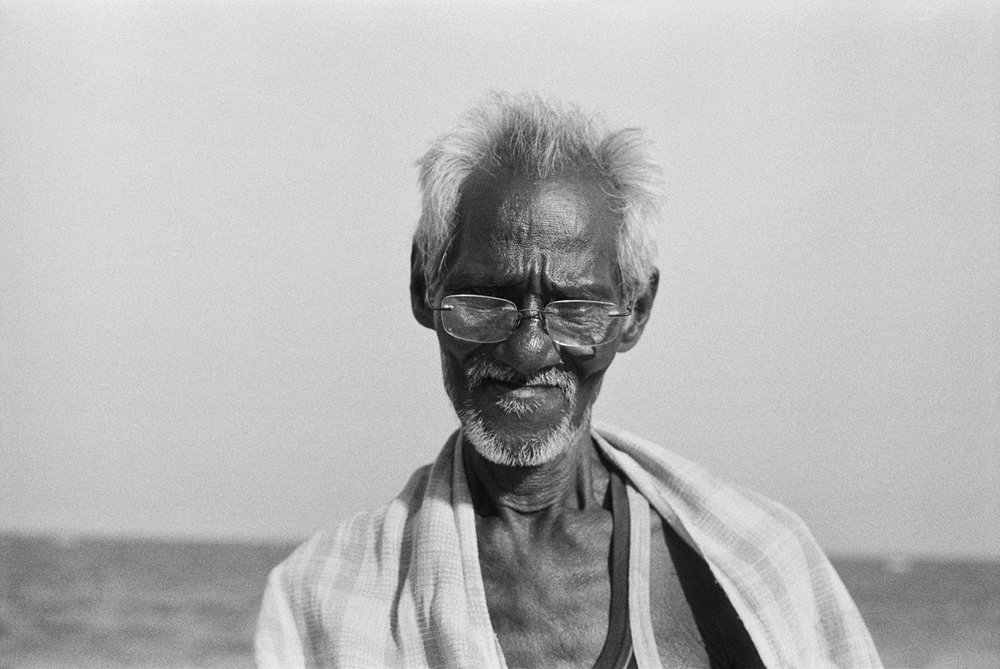

It has been a little while since I last posted; I've been working nonstop with Lauren on our book, 100 Days of India. We just finished designing it in Adobe InDesign and have sent it off to the printers. It's been a hectic week! Here is one of my black & white snaps that didn't make the final cut for the book. It was taken on a hot afternoon at the beach in Auroville, Tamil Nadu.

But now I'm on to writing the second installment of my visits to the Dana Community of potters. This one is about candle holders. These are big sellers in India as many people use them everyday in their shrines at home. I took three videos of the process. The first is the throwing, then trimming and finally altering (cutting the hole in the side).

He had finished his quota of these for the day, but had a couple of balls left and was kind enough to show me how he throws them. I was impressed by his easy throwing style and the slow speed of the kick wheel.

After a couple of hours, the pots are lightly trimmed on a chuck:

Soon after trimming, perhaps half an hour later, they are marked out with calipers and a compass and the holes are cut.

With a hole each side (the size of the opening in the top), they look kind of alien. But I was assured they looked nice when glazed and lit up with a candle.

Soon I will be posting on how they make oil burners--another top-selling item in their repertoire.

But now I'm on to writing the second installment of my visits to the Dana Community of potters. This one is about candle holders. These are big sellers in India as many people use them everyday in their shrines at home. I took three videos of the process. The first is the throwing, then trimming and finally altering (cutting the hole in the side).

He had finished his quota of these for the day, but had a couple of balls left and was kind enough to show me how he throws them. I was impressed by his easy throwing style and the slow speed of the kick wheel.

|

| Still spinning. |

After a couple of hours, the pots are lightly trimmed on a chuck:

|

With a hole each side (the size of the opening in the top), they look kind of alien. But I was assured they looked nice when glazed and lit up with a candle.

|

| Freshly cut. |

|

| A couple of hours later. Halfway to dry. |

Soon I will be posting on how they make oil burners--another top-selling item in their repertoire.

The Dana Pottery Community, Auroville, Part 1 (Incense Holders)

I had been told by numerous people that the Dana Community was the hub of ceramic activity in Auroville, so I made it my mission to visit. It took me a while to find, tucked away in a dusty corner of the labyrinthine town, but when I got there I wasn't disappointed. All hands were on deck, with a bisque kiln being fired and a huge order being packed up for shipment to Germany.

The two main set ups are Flame Pottery and Mandala Pottery but both work together and share clay/firings etc. I saw many different forms being produced on the wheel as well as some slab work. I took lots of pics and a few videos, so it will take a few posts to show them all.

Firstly, some pics of the place itself. There were pots everywhere!

A couple of walls had these amazing traditional tribal paintings on them. So exuberant:

Now on to the first product in detail. It's a simple incense holder, made and sold in the thousands. All this process involves is: rolling out a slab, cutting the shape from a template, cleaning up the edges with a sponge, punching a hole in the thinner end and propping it up to dry. Ready for firing. So quick and elegant.

|

| I would have bought one of these if they weren't so impractical to carry around for the next 2 months in my rucksack. |

|

| Bisque |

|

| They fire primarily with wood, using some gas too. |

The two main set ups are Flame Pottery and Mandala Pottery but both work together and share clay/firings etc. I saw many different forms being produced on the wheel as well as some slab work. I took lots of pics and a few videos, so it will take a few posts to show them all.

Firstly, some pics of the place itself. There were pots everywhere!

|

| Some of Anamika's work: incredible surface effects from pit firing. |

|

| Nice swish. |

|

| Frogs! |

A couple of walls had these amazing traditional tribal paintings on them. So exuberant:

|

| One of the clay drying pans. |

Now on to the first product in detail. It's a simple incense holder, made and sold in the thousands. All this process involves is: rolling out a slab, cutting the shape from a template, cleaning up the edges with a sponge, punching a hole in the thinner end and propping it up to dry. Ready for firing. So quick and elegant.

|

| Next to a finished one. |

Here's a little video of the incense holder production:

Nagaraj Darani Wedging and Throwing Mugs at the Shakhti Pottery, Auroville

Auroville! What a crazy, unusual place this is. Founded in 1968, it aims to be an International City welcoming all nations. It was set up by Mirra Alfassa whom everyone calls "The Mother" and an enlightened fellow named "Sri Aurobindo." When it was founded, the patch of land was heavily eroded, dusty, desert land, but it's now prosperous and covered with trees. At the centre is a monumental golf ball called "Matrimandir" (sounds kind of Lord of the Rings to me, but it's pretty dazzling when you see it)...

It was great fun, razzing around trying to find places. When I did manage to come across Shakhti, I walked in to find Nagaraj vigorously preparing his clay.

His wedging technique is much the same as the one John Colbeck showed me, just with a lot more clay involved:

After the prep, he centered a good lump on his kick wheel and got kicking, adding a bit of water to help his foot grip the concrete. The wheel has a very substantial base, so keeps a good momentum going: Nagaraj kicks it before every pot, but not whilst the pot is being worked on. The aim was 50 before lunch, and at the rate he was going, it could have been an early one.

Today he was making the bodies of some mugs. The weather is so hot here that they will be ready for handles in two hours! I have never seen someone so accurate throwing off the hump. He managed to get the amount of clay just right each time: 250g ish.

Oh and here are a couple of pics of their kiln:

|

| "MATRIMANDIR" |

Auroville is a very productive place, and has several pottery studios within it. My first visit was to one called Shakhti Pottery, where they make a variety of wood-fired stoneware pots. Everything in Auroville is spread out and usually down a dirt track, so Lauren and I hired a motorbike to get around: a Hero Honda no less!

It was great fun, razzing around trying to find places. When I did manage to come across Shakhti, I walked in to find Nagaraj vigorously preparing his clay.

His wedging technique is much the same as the one John Colbeck showed me, just with a lot more clay involved:

After the prep, he centered a good lump on his kick wheel and got kicking, adding a bit of water to help his foot grip the concrete. The wheel has a very substantial base, so keeps a good momentum going: Nagaraj kicks it before every pot, but not whilst the pot is being worked on. The aim was 50 before lunch, and at the rate he was going, it could have been an early one.

Today he was making the bodies of some mugs. The weather is so hot here that they will be ready for handles in two hours! I have never seen someone so accurate throwing off the hump. He managed to get the amount of clay just right each time: 250g ish.

To measure them Nagaraj has an ingenious device: two cocktail sticks,

stuck together. One measures the height, one the width. He uses a piece

of soft leather for the rims.

Oh and here are a couple of pics of their kiln:

Pottery at RASTA, Wayanad, Kerala

Mrs Omana, the director of RASTA, showed us many of their activities. They focus on empowering women,

especially widows, and farmers through specific training. Mrs Omana

has fingers in many pies. The pies range from: a tailoring workshop

on campus for widows, several acres of farm land, a shitake mushroom

growing space, programs for children, and a pottery operation.

Amal is in charge of the pottery. He

also teaches us yoga every morning, which is an unusual experience as

he is deaf and mute, so the classes are conducted in silence. I have

never seen anyone so bendy... some of the postures he gets us to try

are just ridiculous. I have helped him out a few days in the pottery

workshop. The workshop space is a large, open hexagonal room.

Construction on it was begun years ago, intended as a new teaching

wing, but the government cut RASTA's funding, so it has remained

unfinished. The roof is open in one spot, vegetation reclaiming the

space underneath, with bats nesting in concrete crevices. No problems

with the smokey firings though.

Amal makes a range of clay products,

from tiles to wall hangings, to necklaces and bracelets. Jewellery is

the focus of most of his activities. They get sold mostly to the

volunteers who come stay here and some to visitors: there is a little

shop on the site.

First order of business: preparing the

clay. Amal's clay sits in a giant heap and

looks a lot like bedrock.

First he bashes these large pieces up, then

sieves the small pieces with a sieve to end up with a fine dust.

Lauren helped with this too.

Then he adds water to make a slip and pours it into plaster molds.

|

| Ghandi? |

|

| Definitely not Ghandi. |

Squish it up, kneed it up!

Ready to work. The clay was plastic enough for hand building/making small beads and jewellery but would have been too short to throw with. It was a lot of effort to get this much clay too.

Once the clay was prepped, Amal taught me his prayer bead making technique. Firstly you have to make some balls. Tiny balls of the same size.

|

| One, two, three... one hundred and eight. |

|

| Easier said than done. |

For a prayer bead necklace you need 108 of these balls, but if you make too many at once then they dry out, so you have to make 10/15 and move on to the next step: poking a hole in your balls.

|

| Gently does it. |

|

| He made it look so easy. |

|

|

| As you can see, my mind turned swirly. |

I left before seeing them finished, but Amal indicated that he fires these small pieces in the centre of the room, in a covered pan, over a fire... pretty low tech but it does the trick.

|

| The kiln. |

Amal also makes incredible wood and stone carved sculptures. He showed me some pictures, but unfortunately I didn't get a chance to go over and see any of them in the flesh. Next time!