Throwing Handled Beakers

Sadly today was my last day at Winchcombe Pottery. Lauren and I have exited the shack and are preparing to go over to her parents house in L.A. It was an amazing learning experience and I have lots of pictures and videos so will continue to write about my time at Winchcombe for a while yet.

Having shown I could make beakers I was tasked with handled beakers! Very exciting stuff!

They are very similar to beakers but you push a convex curve into them, and obviously have to put a handle on them too. Matt said he wants a thousand making. I'm not sure he is being serious. I hope not anyway.

And here's a video of me making one:

Having shown I could make beakers I was tasked with handled beakers! Very exciting stuff!

They are very similar to beakers but you push a convex curve into them, and obviously have to put a handle on them too. Matt said he wants a thousand making. I'm not sure he is being serious. I hope not anyway.

|

| Here are some examples of handled beakers from other potters at Winchcombe. |

|

| Cone up the clay. |

|

| Cone down the clay. |

|

| Put a hole in it with your thumb. |

|

| Open it up. |

|

| You wantot open it wider than you need the finished base to be. |

|

| This move is pulling the clay up into a think-ish cone. |

|

| Make sure the top is centred. |

|

| Now you are ready for the first proper pull. |

|

| You need to work on getting all the clay out of the base. These pots are only 10oz of clay so you haven't got much spare. |

|

| Once it is almost the right height and width you can begin shaping. |

|

| I use a credit card to push the curve into the body. |

|

| Most of the presure is coming from the card, not the inside fingers. |

|

| Remove the puddle in the bottom. |

|

| Take off the skirt around the base. |

|

| Wire it off. |

|

| Scrape your hands clean. |

|

| I dry my hands too. |

|

| Carefully lift it off. |

|

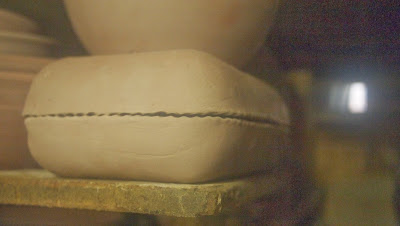

| To join its pals on the board. |

And here's a video of me making one:

Pugging Clay

Today I was tasked with turning the mounds of clay that I mixed up a while ago into pugs of clay. The main reason for this is to drive all of the air out of the clay, making it ready to use. Back in the old days before electricity was used, the pottery had a horse-powered pug mill. This sits directly out the front of the shack:

The pug mill at Winchcombe does this so successfully that kneading the clay before throwing isn't necessarily necessary. By taking differing amounts of the stiffer clay (left) and softer reclaimed clay (right) you are able to pug to the consistency you want to throw with.

The pug mill is probably the most dangerous piece of equipment at the pottery. The metal screw inside the mill will churn anything, not just clay. I was warned and was careful not to get my hands near the moving parts.

Here is a video of the process filmed by Matt G. It is not stupendously thrilling as Matt pointed out, but I think somewhat more interesting than my recent clay mixer video.

|

| As you can see it has become a little overgrown |

The pug mill at Winchcombe does this so successfully that kneading the clay before throwing isn't necessarily necessary. By taking differing amounts of the stiffer clay (left) and softer reclaimed clay (right) you are able to pug to the consistency you want to throw with.

The pug mill is probably the most dangerous piece of equipment at the pottery. The metal screw inside the mill will churn anything, not just clay. I was warned and was careful not to get my hands near the moving parts.

|

| The piles of clay before my efforts today |

|

| Empty bucket awaiting pugs |

|

| Still of the mill |

|

| The pug mill in action... watch your fingers! |

|

| Filthy sticky horibble hands-all fingers still intact |

|

| The pile after I had filled three bins. I used the shovel to cut off chunks of clay from the stiffer pile on the left |

|

| Pugged to the top |

Here is a video of the process filmed by Matt G. It is not stupendously thrilling as Matt pointed out, but I think somewhat more interesting than my recent clay mixer video.

Beakers continued

I have decided not to do a detailed post on trimming the beakers. They don't need much off them, more just tidying up. Below are a couple of pictures before and after.

|

| Beakers turned over ready, awaiting trimming. |

|

| Trimmed and finished beakers. The ones at the back are dryer hence the colour difference. |

These beakers are destined for plain glazes without slip, so will sit out to dry completely as they are until biscuit firing.

Throwing Beakers

I have finally graduated from four inch bowl production. I am not sure exactly how many I made but certainly more than my target of five hundred. Now I have moved into beaker production.

Beakers are a completely different shape; a cylinder rather than a bowl. Instead of 8oz of clay I'm using 10oz. They are thrown four and three quarters of an inch tall and three and a half wide at the top. So here is the process. It took me a few goes before managing to get the right dimensions. A lot ended up in the bucket of clay to be recycled.

|

|

| Cone up. |

|

| Cone down. |

|

| Open up the base. |

|

| Make it wider than the finishing width. |

|

| Now pull the clay up into a cone. |

|

| Try to get the clay right out of the base. |

|

| Check the top is centred. |

|

| Going for another pull. |

|

| Check the rim again |

|

| When you are nearly at the height pointer throw against a credit card to remove the slip. |

|

| Throwing with a card also helps to straighten out the form. |

|

| The rim can be tricky. It needs to be straight rather than flaring out of curling in. |

|

| Undercut the beaker. |

|

| Remove the puddle. |

|

| Wire it off. |

|

| Scrape the slip off your hands. |

|

| Here it is on a board with one made earlier (middle left), one trimmed (middle right) and a finished one (right). |

|

| A board of beakers, with a birthday card from Brian the shoe repairer, and his cat Boots, in the background. |

Unloading wood and loading a bisquit kiln

This morning a dude turned up at the pottery, as promised, bearing a truck load of wood. I was sent out to help unload it.

He managed to reverse down the pot-holed wibbly wobbly track and turned into the area I cleared a few days ago. We undid the metal flaps on the side of the truck with some difficulty.

Then it was a case of trying to lever the cords of wood off. They were not light. We used two long pieces of metal scaffolding to lever them. The first one wasn't budging so we had to cut the cord and chuck them off by hand. The final three rolled off with some gentle persuasion and a lot of heaving.

Once off we stopped for a cup of green tea. The sawmill delivery man (whose name I wish I could remember) couldn't drink normal tea and asked if I had any green. This pleased me greatly as I have a large collection of different teas from all over the world, including various greens.

He managed to reverse down the pot-holed wibbly wobbly track and turned into the area I cleared a few days ago. We undid the metal flaps on the side of the truck with some difficulty.

Then it was a case of trying to lever the cords of wood off. They were not light. We used two long pieces of metal scaffolding to lever them. The first one wasn't budging so we had to cut the cord and chuck them off by hand. The final three rolled off with some gentle persuasion and a lot of heaving.

Once off we stopped for a cup of green tea. The sawmill delivery man (whose name I wish I could remember) couldn't drink normal tea and asked if I had any green. This pleased me greatly as I have a large collection of different teas from all over the world, including various greens.

|

| Arrival. |

|

| I think he looks like a sailor atop the mast, out to sea. |

|

| Done. |

It looks so much easier in three photographs than it was. So that was my morning. The afternoon was spent helping Matt load the bisquit kiln. Matt did most of the work whilst I passed in kiln shelves, fetched props in between helping customers in the shop.

|

| Some little salt piglets and a double jam pot. |

|

| A couple of my press moulded dishes, rim to rim. |

|

| Cone pack with mustard pots underneath. |

|

| Ready to be bricked up. |

Frosty November morning

|

| Chilly sleepers. |

| |||

| Frosted nettles in the fore, the shack in the background. |

|

| Autumn! |

|

| Two flies hanging out on a leaf. |

|

| Yesterday's wood stack, covered in frost. |